As the world becomes increasingly automated, many manufacturing and processing plants are started to adopt conveyor belts and other automation technologies to speed up the process. Conveyor belts are often used in industries such as food and beverage, pharmaceuticals, metallurgy, and other production lines where accuracy and speed are of utmost importance. To get a better understanding of how conveyor belts can benefit your business, read on to learn more about PVC conveyor belts.

What is a PVC conveyor belt?

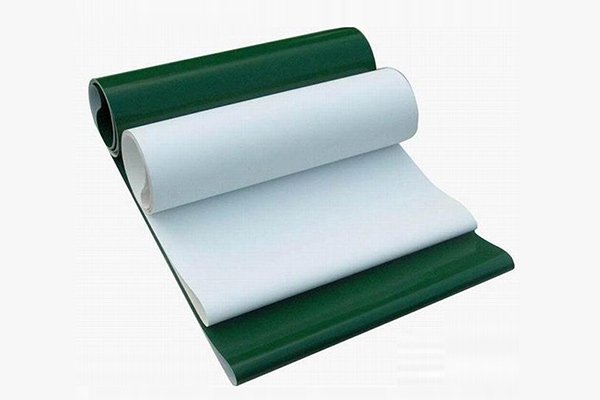

A PVC conveyor belt is a type of industrial conveyor belt that is made from PVC, which is a type of plastic. Most of the food and beverage industries use pvc conveyor belts because they are sturdy, durable, and easy to clean. PVC Conveyor Belts have a high application in various light, medium and heavy industries, including electronics, food, and pharma. Pvc belts are often brightly colored which makes them easier for operators to recognize in crowded spaces. PVC conveyor belts can be custom fitted to fulfill individual requirements since they are available in a range of materials and widths.

Advantages of using a PVC conveyor belt in your industry

There are many benefits to using a PVC conveyor belt in your industry. One of the biggest advantages is that PVC conveyors are incredibly durable. Unlike other types of conveyors, PVC ones can withstand a lot of wear and tear. This means that you can use them in areas where there is a high amount of traffic or contact with the material. Additionally, PVC conveyors tend to be quieter than other types of conveyor belts, which can give you an edge over your competitors. Finally, PVC belts are easy to maintain and operate, which is another big benefit.

Disadvantages of using a PVC conveyor belt in your industry

PVC conveyor belts have several potential disadvantages when used in a manufacturing or processing setting. These disadvantages include:

-Durability: PVC conveyor belts are not as durable as metal or synthetic belts, and can be damaged by harsh chemicals, heat, or wear and tear. This can lead to decreased efficiency and increased labor costs.

-Weight: PVC conveyor belts are heavier than other types of belts, which may make them harder to move and use in high-traffic areas. This can also increase the risk of injury accidents.

-Cost: PVC conveyor belts are more expensive than other types of belts, which may make them less affordable for smaller businesses or those with limited resources.

How to choose the right type of PVC conveyor belt for your business?

When it comes to picking the right type of PVC conveyor belt for your business, there are a few factors you need to consider. Your industry, operating requirements, and overall needs will determine which type of PVC belt is best for you.

The most common types of PVC conveyor belts include rubber-belted, chain-driven, and screw-driven belts. Rubber-belted belts are often the most affordable option and are generally easier to operate. Chain-driven belts are usually more expensive but offer greater speeds and throughput. Screw-driven belts are the most expensive option but also offer the longest life expectancy and the best overall performance.

Before making a purchase, always consult with a manufacturer or an experienced engineer to get the correct specifications for your specific application. Be sure to read all operator’s manuals and safety guidelines before starting up your belt system.

Factors to Consider When Choosing the PVC Conveyor belts

When choosing a PVC conveyor belt, there are a few factors to consider. These include the intended use of the belt, the weight and size of the items it will be moving, and how easily it can be cleaned.

When considering an industrial PVC conveyor belt, its intended use is key. There are two main types of belts- rigid and flexible-. Rigid belts are typically used in industries that require a more controlled movement. They’re also better for heavier items because they have a higher capacity. Flexible belts, on the other hand, are better for lighter items because they can flow more easily.

Another factor to consider when choosing a PVC conveyor belt is its weight and size. The belt should be able to handle the weight and size of the objects it will be moving without breaking or wearing out. The dimensions of the object should also fit within the width and length of the belt.

One final factor to take into account when choosing PVC conveyor belts is cleaning. Cleaning is often a critical part of maintaining an industrial facility, so it’s important to choose a belt that is easy to clean. Belts with integrated cleaning systems are usually easier to clean than those without them, but all belts can be cleaned using standard cleaning methods such as soap and water.

Conclusion

A PVC conveyor belt is a great asset for your industry, as it can help with product flow and distribution along the line. Additionally, it can improve accuracy and speed up the manufacturing process. If you are looking to adopt this type of conveyor belt in your business, be sure to contact a pro like Schlanger Machinery to get started.